Last year we explored the factors driving malting barley prices and took an early look at how the malt we’d be brewing with this year was shaping up. It’s hard to believe, but malt agreement season has already rolled around again, and it’s time to start thinking about the barley we’ll be brewing with in 2026 – from crops harvested during those halcyon days of summer 2025 whilst many of us were sinking pints in Cornwall or brewing lager like there was no tomorrow…

This year, as well as taking a load of brewers on a tour of Germany to visit the BayWa hop fields and the German Maltsters BESTMALZ, we also teamed up with Bairds Malt to run malting courses at their Burton and Witham maltings. These courses are a brilliant way for you as brewers to get to grips with malt as the foundation of your beer, and they highlight one of the biggest benefits of a malt agreement: building a close, informed partnership with your maltster. You can read more on Will from Bullhouse Brewing Co’s insights on BESTMALZ in our Germany Tour Blog Post.

The blog post below is based on a presentation given at the Witham Bairds Malting Course in October 2025 by Kyrsten Moore, Director of Operations at Bairds Malt. Kyrsten has a degree in Biochemistry, with over 20 years of experience in malting – including several spent managing the Witham Maltings – so has a wealth of knowledge to impart, and is better qualified than anyone to tell us what we can expect from this year’s malt.

Over to you Kyrsten:

2025 – A Challenging Year for Barley Growers

If you’ve been keeping an eye on the weather this year, I probably don’t need to tell you how dry it’s been. It started back in February – rainfall was already below average – and from there, it just got worse. Spring 2025 was actually the sixth driest spring on record since 1836, and the dry spell carried right through July and August.

Those of us who like to grow things at home could see the impact straight away. My flowers that would usually last six to eight weeks were over in two. Out on the farms, fields that would rarely need irrigation were being watered regularly – something you just don’t see much anymore. It was a year that made all of us in the maltings a little uneasy.

When the weather impacts the farmland, it of course has a significant effect on the barley. And if we don’t have good barley, we can’t make good malt. So early in July, we started to get concerned about what the dry conditions would mean for the quality of the 2025 barley crop for brewing malt – and ultimately, what brewers could expect from their malt this year.

Weather Impact on 2025 Barley Crop

Like many maltsters, at Bairds Malt we have our own Agricultural Merchants – Scotgrain – who work closely with the farmers who grow our barley. They’re an essential link in the chain between us, the farm, the farmer, and barley – and in turn you and your malt and your beer. Scotgrain handle all aspects from ‘field to fork’ and are part of our pioneering on-farm sustainability efforts to create a long-term holistic barley supply through programs like regenerative agriculture, cover cropping, pioneering fertiliser, and a balanced healthy on-farm eco-system with projects like Chirrup AI. So, when we need to find out what’s happening on the ground, we send in our experts. Scotgrain began field assessments of the barley in early summer this year, and the first signs were mixed. The winter barley varieties – like Craft, and the newer Bucaneer, (which will eventually replace Craft) – looked reasonably good. The spring varieties (like Laureate), though, were showing the effects of the weather. On lighter land, growth was patchy, and after the brief rainfall in July and August, we even started seeing secondary growth, which can lead to unripe grain and consequent rejections at intake for us at the maltings.

The dry conditions pushed the harvest forward by almost a month, which is significant. Typically, harvest in East Anglia and Essex runs from mid-July onwards, but this year, farmers got combining much earlier. For them, that was a mixed blessing: dry weather means lower moisture content (and less to pay for drying), but it also meant lower yields – and in many cases, stressed barley.

The result was a tough year for farmers. Many will think twice about planting spring barley next year and may switch back to winter wheat, which is more resilient and reliable. As we know, multiple factors affect the price of barley – the most obvious being supply. If farmers choose to switch out to winter wheat that could tighten the spring barley supply for the 2026 crop, so that’s certainly something for you to be aware of as brewers this time next year when you’re thinking ahead again to malt supply agreements. But that’s a whole year away yet – what we’re really interested in is this year’s crop – and how it’s going to affect you, and how best you go about securing your malt supply for 2026…

Assessing the Crop: How Maltsters Evaluate Barley

Before any barley makes it into the maltings, we get an early look through pre-delivery samples – small bags of grain that farmers drop off from their sheds. These go through our barley lab for intake-level testing which covers:

- Germination

- Screenings and retention (boldness and plumpness of the barley grain)

- Total nitrogen (TN)

- Moisture

- Physical damage (skinning, splitting, mould)

These first samples give us a snapshot of what the harvest looks like and help us decide what to bring onto site. There’s no point in hauling in a 29-tonne load if it’s not going to meet spec – so we only call forward what’s worth malting.

Just taking barley into silos for storage is a labour intensive process – first it must be dressed and dried. Dressing removes chaff and lighter grains; drying brings moisture below 12% to prevent pests and ensure safe storage. We also cool the barley to below 12°C heading into winter, which helps maintain condition. Each batch is monitored for temperature and moisture so it stays stable in storage until it’s ready for processing. It’s futile us carrying out this process if the barley isn’t up to spec, so we need to assess early through pre-delivery samples, and then work up from those into the bulk loads. It’s then an ongoing process of assessment, collecting a representative sample of every variety that’s coming in and sending it up to our lab in Arbroath. We’ll pre-screen the load, carry out barley analysis, micromalt analysis, and then macromalt analysis – making the process of ‘sampling’ is almost constant.

What Does ‘Good’ Barley For Malting Look Like?

There’s not a ‘golden rule’ for perfect barley (as we’ll discover later) but there are certain parameters which we can control through our malting process – like moisture and colour – those aren’t really crop quality factors, those are kilning factors. We kiln to the right moisture, and whilst colour is affected by solubles, we can make up for these with our kilning process.

That means that when assessing barley crop quality we’ll look at Extract, Total Nitrogen (TN), Friability, and Beta Glucans – all of which are linked of course. Generally, the higher the TN level, the less starch there is in the barley grain – there is normally an inverse proportion. We can even see this visually when cutting the grain in half with a farinator. This is no longer a routine test, as there are far more technical methods available for TN determination now.

"A low nitrogen high-starch grain will be ‘bold’ - fat and floury - and a high nitrogen low starch grain will be skinny, grey and ‘steely’. A grain with higher TN content is generally more difficult for us to process because it’s harder to hydrate during steeping."

Steeping is the most important part of our process – if we get that right, then the rest is quite easy. If we get that wrong, it’s much harder for us to recoup that time, and so if we have a steely grain and we struggle to hydrate it, that makes our life a whole lot harder during germination to try and catch up.

What we are looking for ideally is low nitrogen ‘mealy’ grains – so floury grains – that is an indication of good starch levels and therefore high extract levels.

Early Results: Barley Analysis on 2025 Barley For Malting

So, what did the early barley analysis show this year?

In short, winter barley fared well. The grain was bold and plump, nitrogen levels were only slightly above average, and there were no major issues like split grains or Fusarium. The spring barley – surprisingly – was also bold, which isn’t what we expected given the weather. Normally, a dry year leads to high nitrogen and skinny grains, but this year the boldness has offset the higher TNs, meaning extract potential remains strong.

That said, the variation in total nitrogen was wider than usual — from about 1.5% to over 2%. That’s a big spread. But because the crop was bold, we were able to select the best lots of barley for malting, keeping our average TN well within a manageable range.

It’s been a poor year for yields and farmer returns, but from a malt quality perspective (and thus from your perspective as brewers), things are looking far better than we feared back in July. Please spare a thought for the farmers though. There have been a lot of ‘rejections’ owing to higher nitrogen, so there’s going to be more malt going into the animal feed market this year. Animal feed malt already carries a lower premium, so a saturated market here means the farmers get even less return for their efforts.

Micromalting: The First Glimpse of Malt Performance

Once we have representative samples of each variety, we send them to our lab in Arbroath for micromalting – a process that replicates large-scale malting in miniature. The barley is steeped, germinated, and kilned under controlled conditions that mirror our maltings at Witham and Burton.

Before micromalting, each sample goes through a conditioning phase to simulate natural post-harvest recovery – mimicking the time barley spends resting in store after drying. This is crucial for getting a realistic view of malt potential.

Now, it’s worth noting that any indications we’re talking about here are early micromalting results, taken before the barley had much recovery time. Micromalting analysis on malt as this stage is not same as COA figures and shouldn’t be used to judge the malt you’ll receive. That said, they’re an important early indicator of what’s to come.

"The early 2025 micromalting results show:

- - Extracts holding up well, even at higher TN levels.

- - Good modification and friability for this stage.

- - Lower beta glucans than last year at the same stage - a sign of easier processing.

- - No major enzyme concerns - FAN and DP levels are typical."

In terms of specific varieties, Craft (a winter barley variety) had slightly lower friability and extract, and higher glucans, but this is to be expected given that it was micromalted incredibly early this year. On Laureate (spring barley), that looks to have performed well, with extracts higher and beta glucans lower than the Craft which is fairly typical, as Craft tends to show higher beta glucans in the early days in micromalting analysis. We will be bringing in more Bucaneer this year – a winter variety slated to replace Craft – as Bucaneer performs very well agronomically on the farm and also in terms of malting, so you may well see Craft gently phased out over the coming years. This can often be the case as we develop more and more efficient barley strains.

All in all, despite a dry growing season, the barley is performing much better than expected under lab conditions. It should be remembered that generally extract increases & Beta Glucans drop as we move further away from that intake and drying date and the barley matures.

From Micromalting to Macromalting: Real Malt Performance

Once we start running the first macro batches through our maltings, we get a true picture of how the crop behaves at scale.

At Burton, the first three batches of the 2025 crop – a mix of ale malt, a high DMS malt (for whisky production), and lager malt – have already gone through ‘macro’ (large scale) malting. Extracts are looking healthy (81–84% EBC), and friability and other measures of modification are where we’d expect.

Even with relatively high TNs, extract levels remain strong, and enzyme activity is well within spec. When we compare these numbers to 2024, the difference is minimal – a very reassuring sign for brewers.

In short, early large-scale results confirm what we hoped: the 2025 crop will deliver malt of consistent quality and performance.

Understanding Barley Recovery and Water Sensitivity

Beyond the numbers, there’s a lot of hands-on work that goes into deciding how each batch of barley is processed. Two of the most useful tools we have are the 4ml and 8ml recovery and water sensitivity tests.

The 4ml test involves soaking 50 grains in a shallow petri dish and checking how many have chitted (sprouted) after 24, 48, and 72 hours. This tells us whether the grain has had long enough to ‘recover’ in the silo and is ready for steeping. The 8ml test, done with more water, reveals how sensitive the grain is to moisture. Steeping is critical to malting process and not something you want to get wrong. It’s much better for us to understeep and hit a lower moisture percentage than oversteep. If you oversteep the grain, the likelihood is that you’ve killed some of it. You’ll prevent the enzyme cascades that follow from that process, so you will not get the required modification. Your grains will sit as whole corns in the malt. We typically aim to understeep at Witham slightly because we can always add moisture in germination if we need to.

These results from our water sensitivity tests help our maltsters adjust steeping recipes – water temperature, number and duration of wets – to suit each batch. Early in the season, for example, we often use three shorter wets until the crop fully matures and becomes less water sensitive.

Every variety and every crop year behaves differently, and that’s where maltsters’ experience really matters. Our teams continuously tweak steeping, germination, and kilning based on what they see and smell each day. We’ll tap into historical knowledge of barley varieties too – for instance a lot of the time with Maris Otter® we need to steep in three wets – and some varieties are just generally poor at recovery. We’ll look over historical records and recipes to help inform our decision making too. But no two batches are ever identical – and that’s what makes good maltsters invaluable as we’ll constantly be needing to tweak recipes when a batch is in process.

Managing Variability in Brewing Malt: Total Nitrogen Doesn’t Mean Everything

It’s tempting to look at total nitrogen and make assumptions about malt quality, but the truth is TN isn’t everything.

We’ve seen high-nitrogen years that have produced beautiful malt – easier to steep than expected, low glucans, good extracts – and low-nitrogen years that turned out to be far more challenging. Barley quality is the sum of so many variables: variety, weather, soil type, and post-harvest handling all play their part.

That’s why we approach each crop year on its own merits. We test, monitor, and adapt our process to make sure we’re getting the best possible malt out of the grain that Mother Nature gives us.

What to Expect from Brewing Malt in 2026

So, what can brewers expect from next year’s malt from Bairds Malt?

- Consistent quality: Despite tough conditions, extract and modification levels are solid, and beta glucans are trending lower than for the 2024 crop.

- Slightly higher Total Nitrogens, but well within workable ranges.

- Good processability across both winter and spring varieties.

In practical terms, that means brewers can continue to rely on stable brewhouse performance and good extract yield from this year’s malt.

Process Aids For 2026 Malt

And while malt quality looks strong this year, every crop brings small differences. Reviewing your brewing process parameters – or considering brewing aids that optimise extract and clarity – can help ensure you’re getting the most from your malt, whatever the crop throws at us.

On that subject, we’ve got some insights from Sarah Young over at AB Vickers:

“It has to be said that this very dry and warm summer produced conditions which were not conducive to producing good malting barley, however against all the odds the barley looks to be in good condition.

“The increase in TN, though not as high as previously anticipated, could still impact negatively on beer clarity. This is especially important for those who are looking to produce crisp clear Pilsners or a beautifully bright cask ale.

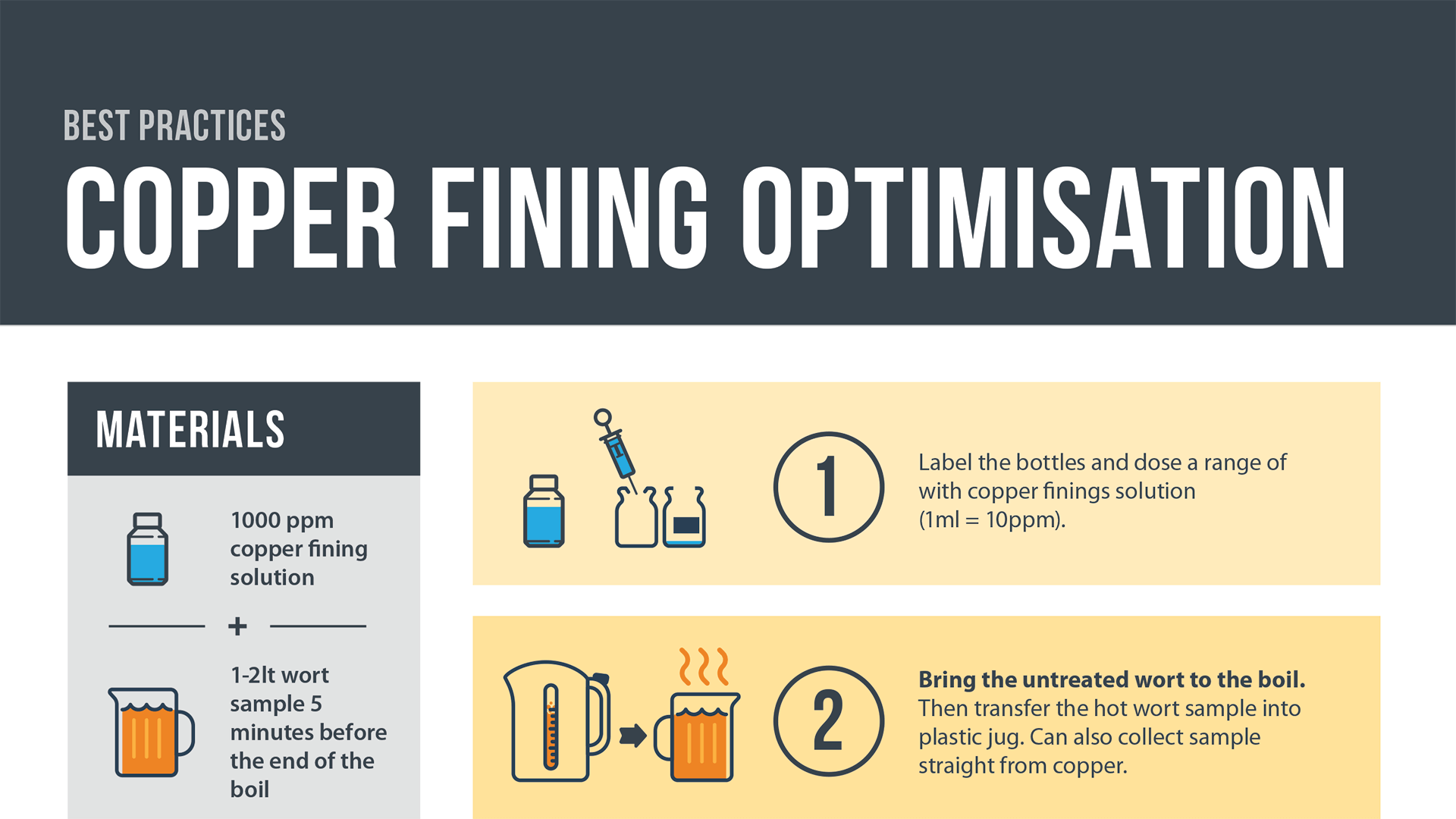

“It is always important to carry out optimisations on copper finings (Compac CG – available in tablets or granules), auxiliary finings and silica sol (Protosol) when the new season’s malt arrives, especially in the case of elevated protein levels. Too low an addition rate will see a deterioration in haze, too high can see an increase in tank and cask bottoms which can lead to unnecessary losses. Please check out the Lallemand Brewing YouTube channel which shows you how to carry out an optimisation or reach out to the team at AB Vickers to walk you through the best practices.

“pH can also fluctuate, even small changes can cause variation in fining performance. Lower pH’s can slow fining in wort and beer, while an increase can cause a lift in sediment levels.

“Gelatinisation temperatures can increase in hot and dry years, this means mashing temperatures may need to be increased, skewing the “ brewers window” more towards alpha amylase activity rather than beta amylase. This could impact the sugar spectrum in your wort and reduce the maltose levels available for yeast. We can provide assistance and enzyme recommendations to help combat this.

“In terms of nutrients, the malting results show good extract, however, if you brew styles with adjunct forward grists (e.g., sugar, rice/wheat additions, seltzer hybrid approaches), Yeastlife Extra is a powder yeast nutrient based on readily available sources of nitrogen blended with additional amino acids, minerals and vitamins providing yeast with essential nutrients, whilst Yeastlife O supplies organic nutrients (without zinc) optimized for high-sugar, low-nutrient fermentations. Both will help prevent sluggish or stuck fermentations and off-flavours. If you’re a brewery adapting recipes to stretch malt across blends, or using more adjuncts to offset malt availability or cost, these nutrients can be a good insurance policy.

“Foam and head retention depend on malt-derived protein, which can increase excessive foaming in fermentation. An antifoam such as Foamsol can help efficiently disperse foam at low addition rates, allowing you to capacity fill your fermenters without any detrimental effect to head retention.”

"It is always important to carry out optimisations on copper finings, auxiliary finings and silica sol when the new season’s malt arrives, especially in the case of elevated protein levels. Too low an addition rate will see a deterioration in haze, too high can see an increase in tank and cask bottoms which can lead to unnecessary losses."

Looking even further ahead, however, the challenges faced by farmers mean there may be less spring barley planted for 2026. To secure your preferred varieties and pricing, it’s a good time to lock in malt agreements early.

Confidence in the 2025 Barley Malt Crop from Bairds Malt

It’s been an extraordinary growing season – one of the driest in nearly two centuries – but the results are a testament to the resilience of both our farmers and our maltsters.

"The 2025 barley crop has delivered far better quality than expected, and the early signs from both micromalting and full-scale production are encouraging. Brewers can expect reliable performance and consistent malt quality throughout the year."

As always, we’ll keep monitoring the crop as it matures, and we’ll continue sharing updates. In the meantime, if you’d like to discuss malt ways to optimise your brewhouse performance for next year’s malt, make sure to chat to the wonderful folks at Loughran Brewers Select or AB Vickers.

Because no matter what the weather does, we’re here to make sure your malt – and your beer – stays at its best.

Guarantee Consistent Pricing & Supply with a Malt Agreement

What we’ve read above from Kyrsten reinforces how valuable it is to keep an open line of communication with your maltster – and how useful a malt agreement can be in protecting your brewery from sudden market swings. Just as you would when planning a hop contract, discussing your malt requirements with your sales manager is one of the most effective ways to manage risk. It secures access to the high-quality malt you rely on from the likes of Bairds Malt and BESTMALZ, locks in competitive pricing, and gives both you and your finance team predictable costs for the year ahead.

When it comes to pricing, it’s always worth exploring the options with your supplier. A well-structured agreement benefits both sides, creating stability for brewers and suppliers alike. And, as with any key ingredient partner, sharing information early and building that relationship pays off: you’ll get consistent malt quality, access to resources like malting courses reliable and industry-leading next-day delivery when you need it, and support from people like Kyrsten who truly understand malt. Contact us today and we’ll put you in touch with your sales manager to work out the best malt agreement for your brewery and your beer.