Six months ago we had an idea – could we get a group of brewers together for a trip to Germany during Oktoberfest? Our goal was relatively simple – much like we’ve done when we’ve travelled with brewers out to Portland, Oregon for hop selection, we wanted to connect brewers to their source of their ingredients – the fields where they’re grown, and to the farmers who grow them, and to the producers who turn their barley and hops into the premium German malt and T90 hop pellets they need to brew great beer. We hatched a plan – we’d assemble together a group of brewers from breweries in the Republic of Ireland, Northern Ireland, and Britain, and from Dublin, Manchester, Edinburgh and London we’d head out to Frankfurt, then on to Wallertheim, Heidelberg, Ravensburg, and finally, Munich.

Heidelberg Castle. Photo by Mark Cotterrell of Beak Brewery.

Heidelberg Castle. Photo by Mark Cotterrell of Beak Brewery.

Our final group for our trip was a roll call of brewers from some of our favourite breweries: William Mayne from Bullhouse Brew Co., Harry Szapira of Wicklow Wolf, Jordan Donnelly from Pearse Lyons Brewery, Tempest Brewing Co.’s Doug Rowe, Caitlin McErlean (Track) and Mark Cotterell of Beak Brewery, as well as James, Sarah, Fergal, Ian and Natasha from our team.

Our brewers with the Loughran Brewers Select team at BayWa hops. L-R: Caitlin McErlean (Track), Ian Anthony (Loughran Brewers Select), Sarah Brennan (Loughran Brewers Select), Philip Meier (BayWa), Natasha Lawlor (Loughran Brewers Select), Mark Cotterrell (Beak Brewery), Harry Szapira (Wicklow Wolf), James Loughran (Loughran Brewers Select), Fergal Carroll (Loughran Brewers Select), William Mayne (Bullhouse Brew Co.), & Jordan Donnelly (Pearse Lyons Brewery).

Our brewers with the Loughran Brewers Select team at BayWa hops. L-R: Caitlin McErlean (Track), Ian Anthony (Loughran Brewers Select), Sarah Brennan (Loughran Brewers Select), Philip Meier (BayWa), Natasha Lawlor (Loughran Brewers Select), Mark Cotterrell (Beak Brewery), Harry Szapira (Wicklow Wolf), James Loughran (Loughran Brewers Select), Fergal Carroll (Loughran Brewers Select), William Mayne (Bullhouse Brew Co.), & Jordan Donnelly (Pearse Lyons Brewery).

We thought the best way to recap our trip was to hand over the reins to the brewers themselves to allow them to tell the story. So, it’s over to William Mayne of Bullhouse Brew Co., Doug Rowe from Tempest Brewing Co., and Mark Cotterell of Beak Brewery to take you through Germany via their words and photos.

Cheers to Will at Bullhouse Brew Co. who’s kindly offered to serve as our chief narrator, with some quotes and thoughts from other folks along the way. Over to you, Will:

Craft Brewers from ROI, NI, & GB in Germany

A huge thank you to Loughran Brewers Select for taking me on the recent trip to Germany. It was great to catch up with some familiar faces in the UK and Irish brewing scene as well as meet some new ones!

The trip started with a 2.45am alarm on Monday and I finally came through the door at 1am on Thursday morning so we certainly squeezed a lot in!.

"BESTMALZ are the only German specialist maltster in the British and Irish market who malt and craft their own pale base malts (BEST Pilsen, BEST Heidelberg etc), and they take great pride in the control, consistency and - crucially - quality this gives them over their malt, and it really sets them apart from their rivals."

Taproom at BESTMALZ Heidelberg Head Office. Photo by Mark Cotterrell of Beak Brewery.

Taproom at BESTMALZ Heidelberg Head Office. Photo by Mark Cotterrell of Beak Brewery.

BESTMALZ Wallertheim Maltings

After landing in Frankfurt, we headed straight to BESTMALZ and their impressive malting facility in Wallertheim, which produces 30,000-50,000 tonnes of malt a year for domestic German consumption for breweries like Bitburger and the Radeberger group and also for export, including to US craft breweries like Buoy Brewing, Zoiglhaus, and Emancipation Brewing. On arrival, we were greeted with an offer of a much needed cup of coffee, only to be informed in the cheekiest way after we’d all finished our ‘coffee’ that we had not in fact had coffee at all, but a test batch of a new roasted grain-based drink. The passion of the BESTMALZ team for malt was infectious, and the diversification projects speak to the innovation of their team, but also to some of the challenges facing the German brewing industry amid wider global trends with beer consumption falling as consumers continue to be squeezed in terms of disposable income.

Steeping vessels at BESTMALZ Wallertheim Maltings. Photo by William Mayne of Bullhouse Brewing Co.

Steeping vessels at BESTMALZ Wallertheim Maltings. Photo by William Mayne of Bullhouse Brewing Co.

"Roasted malt is normally created in a turning 'drum', where the grain will briefly have contact with the extreme heat on the drum's walls. BESTMALZ actually uses a proprietary vertical hot air roasting system giving an even, smooth and consistent colour to their roasted malts, with none of the slight 'burn' or touch of astringency you can sometimes get from drum roasted malt."

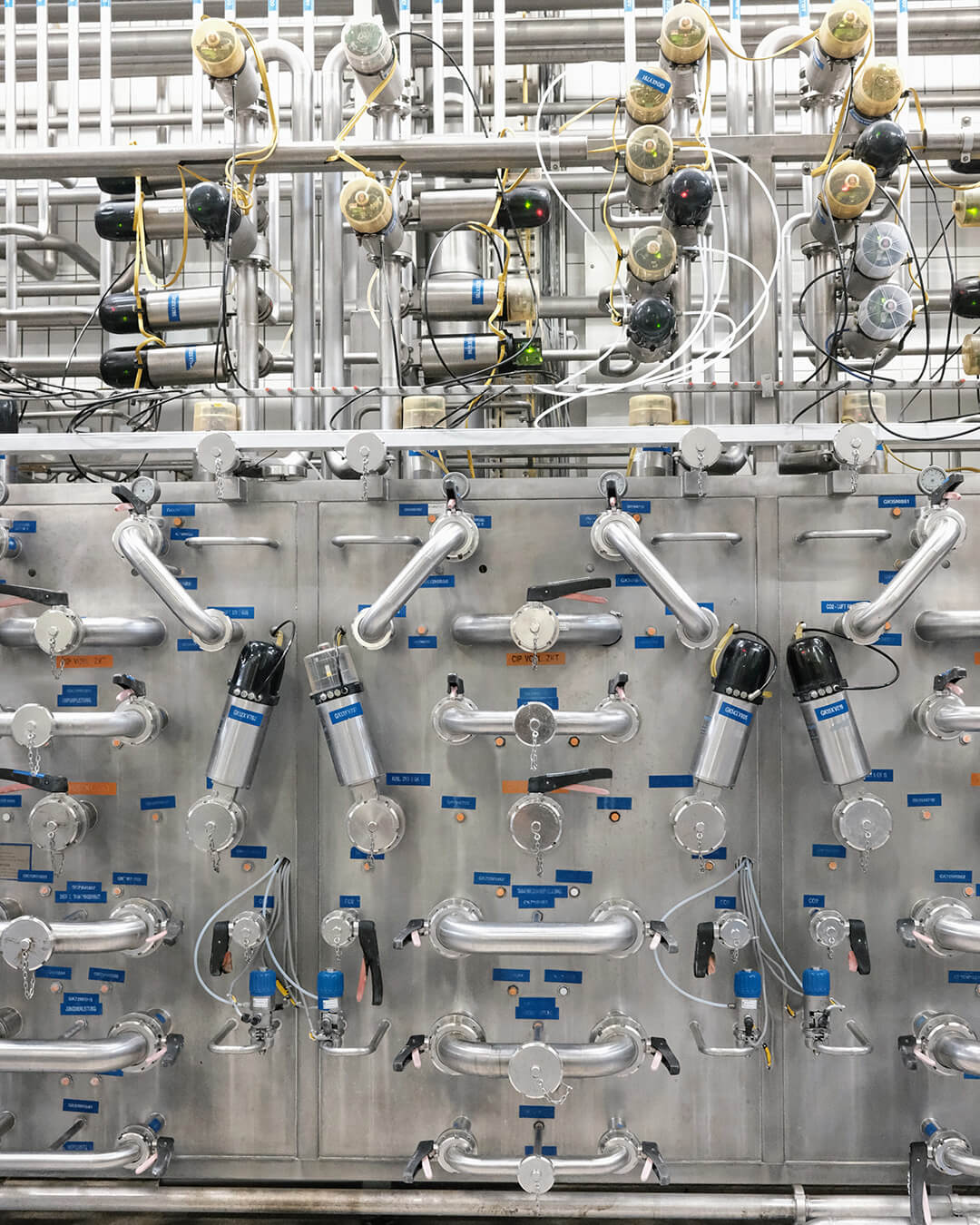

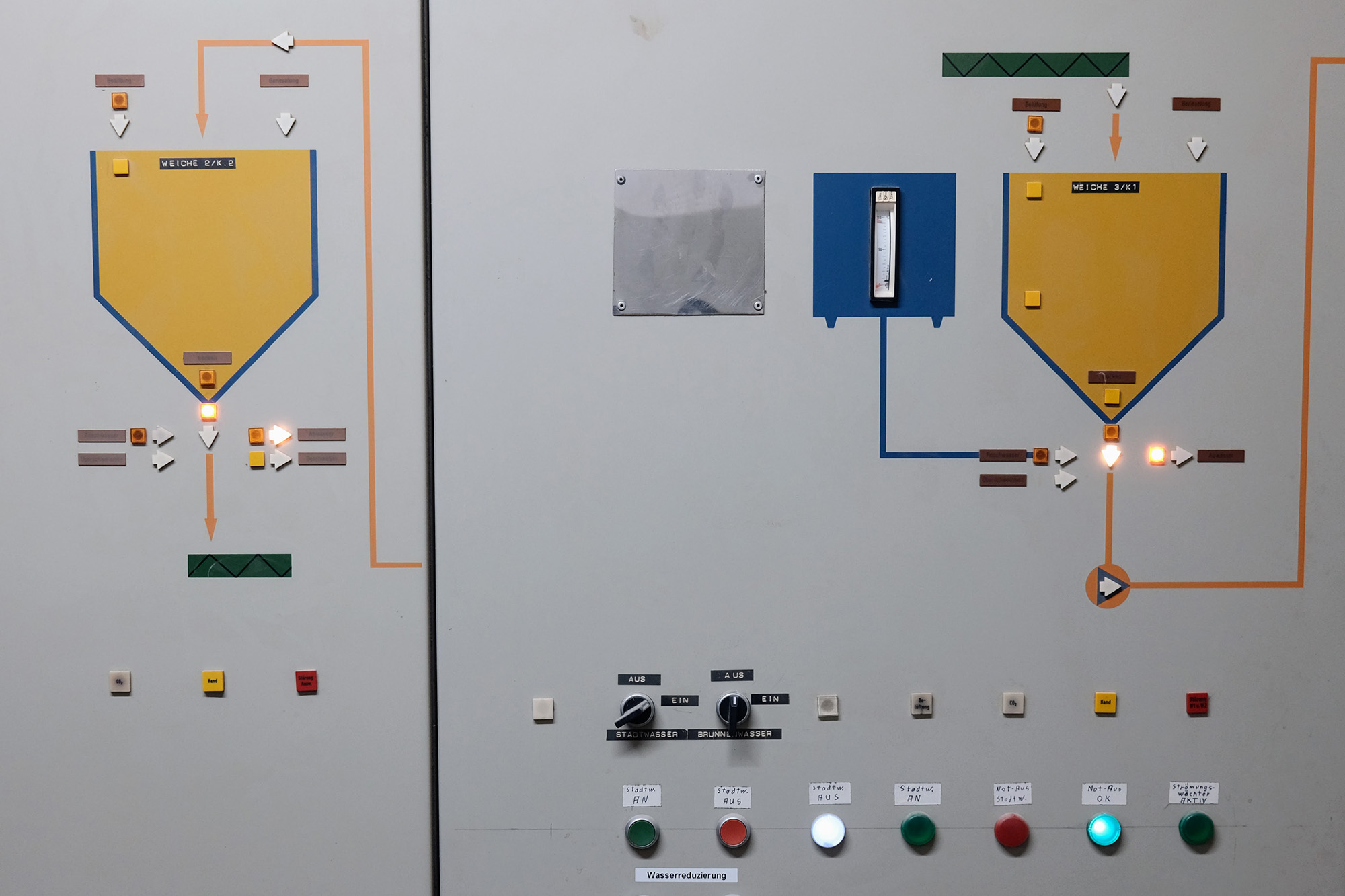

Control Board at BESTMALZ Wallertheim Maltings. Photo by Mark Cotterrell of Beak Brewery.

Control Board at BESTMALZ Wallertheim Maltings. Photo by Mark Cotterrell of Beak Brewery.

[Tempest has been using malt from BESTMALZ for several years now across beers like IPAs, Lagers and Pales and Extra Pales, including in their flagship Extra Pale ‘Long White Cloud']

"We've used BEST Heidelberg Pilsner, which is one of the most premium malts you can use for base malt. We also use BEST Chit malt as well, which creates beautiful head and foam in the finished beer. Visiting the maltings helps cement what we already knew and felt - BESTMALZ was clearly run to a high standard of quality - as well as being immaculate!”

Germination room at BESTMALZ Wallertheim Maltings. Photo by Mark Cotterrell of Beak Brewery.

Germination room at BESTMALZ Wallertheim Maltings. Photo by Mark Cotterrell of Beak Brewery.

I also found the attention to detail at BESTMALZ hugely impressive. A culture of maintenance and respect for their equipment is clearly evident alongside their focus on malting innovation and quality – things like their vertical hot air roaster for example. All this makes sense given that they’ve been around for 120 years and they’re still going strong!

“BESTMALZ Wallertheim can only be described as staggeringly clean - possibly the cleanest maltings I’ve ever seen. That’s all the more impressive when you consider the volumes they’re working with - a fully automated bagging line capable of moving 22 tonnes an hour. Innovation is paired with tradition though - they still crush malt manually despite all that automation! To be working with a company with that attention to quality and detail - and to know that they trust us as custodians of their brand to uphold that quality when we work with and distribute their malt to brewers in GB, Republic of Ireland and Northern Ireland means a hell of a lot, and makes me proud of our lads in Peterborough and Dundalk.”

Photo by Mark Cotterrell of Beak Brewery.

Photo by Mark Cotterrell of Beak Brewery.

Plenty of beer, schnitzel and pork knuckle later, we arrived at BESTMALZ head office in Heidelberg which was nothing less than incredibly impressive – the standout being the 120L pilot kit showpiece in the office lobby!

The BESTMALZ head honcho and MD Dr. Axel Göhler joined us for an awesome dinner at the Kulturbrauerei Heidelberg. Axel is the fourth generation to run the family malting business, and has clearly benefitted from starting life outside the family industry, bringing skills and expertise from other sectors into the BESTMALZ and has helped foster that culture of innovation alongside that attention to detail and quality. Meeting independent, family owned suppliers always strikes a chord with us, and being welcomed by an actual family member (and boss of the company no less) was the icing on the cake. We’ve been fortunate to work with BESTMALZ BEST Heidelberg and BEST Wheat in several of our one-off special beers with great results, and having seen first hand how dedicated, passionate and industry-leading BESTMALZ is, we’re looking forward to working more of their malts into our mash bills and our beers.

Photo by Mark Cotterrell of Beak Brewery.

Photo by Mark Cotterrell of Beak Brewery.

Heidelberger Brauerei Using BESTMALZ in Classic German Beers

We followed up our time at the BESTMALZ head office with a visit to the nearby Heidelberger Brauerei which is also in the picturesque town of Heidelberg. Heidelberger Brauerei has been brewing since 1753, and as you can probably imagine, we got some great insights into archetypal German beer – there were a good few highlights for us all there. Standouts for us were the DMS (dimethyl sulfide) stripper in the brewhouse, and the swing panel in the cellar was also popular, though not quite as popular as the beer and pretzels!

The brewers visiting at Heidelberger Brauerei. L-R: Caitlin McErlean (Track), Heiko Stern (Heidelberger Brauerei), Mark Cotterrell (Beak Brewery), William Mayne (Bullhouse Brew Co.), James Loughran (Loughran Brewers Select), Fergal Carroll (Loughran Brewers Select), Harry Szapira (Wicklow Wolf), Doug Rowe (Tempest Brewing Co.), Ian Anthony (Loughran Brewers Select), Jordan Donnelly (Pearse Lyons Brewery), Sarah Brennan (Loughran Brewers Select), Dr Axel Göhler (BESTMALZ) & Lutz Wirsching (Heidelberger Brauerei).

The brewers visiting at Heidelberger Brauerei. L-R: Caitlin McErlean (Track), Heiko Stern (Heidelberger Brauerei), Mark Cotterrell (Beak Brewery), William Mayne (Bullhouse Brew Co.), James Loughran (Loughran Brewers Select), Fergal Carroll (Loughran Brewers Select), Harry Szapira (Wicklow Wolf), Doug Rowe (Tempest Brewing Co.), Ian Anthony (Loughran Brewers Select), Jordan Donnelly (Pearse Lyons Brewery), Sarah Brennan (Loughran Brewers Select), Dr Axel Göhler (BESTMALZ) & Lutz Wirsching (Heidelberger Brauerei).

“I enjoyed the Heidelberger Brauerei Helles a lot (especially with a pretzel!) and particularly after learning all about their processes on the brewery visit. At Tempest we’ve already discussed tweaking the malt bill on one of our lagers slightly to make it more like some of the beer I drank on this trip, and of course with access to BESTMALZ malts through Loughran Brewers Select that’s an accessible option for us too”

Hop Sensory session at BayWa Hops. Photo by William Mayne of Bullhouse Brewing Co.

Hop Sensory session at BayWa Hops. Photo by William Mayne of Bullhouse Brewing Co.

BayWa Hop Sensory & German Hop Trends

After a few days on German malt, the last day of our trip was all about German hops. We headed over to BayWa in Tettnang in German hop growing country to see their huge hop processing plant and pelletiser, and visited the Locher-Hopfen farm too. We were welcomed to Tettnang by BayWa’s Philip Meier, and Anton and Florian Locher of Locher-Hopfen – a fourth generation hop farm collective who are one of the growers supplying BayWa with hops. We got a schooling on German hop varieties and hop agronomy and farming through a BayWa hops sensory session.

"At the moment, we have a trend towards the traditional noble aroma varieties - Saaz, Tettnang, & Mittelfrüh… we have brewers that look to have a focus on the quality. And then they say, "okay, now I'll do everything to have really the best deal [overall]... okay, I'll pay maybe some euros more per kilo, but then I can have the noble aroma of a Tettnang, a Saaz or a Mittelfruh."

Fields at Locher Hopfen Hop Farm Collective. Photo by Mark Cotterrell of Beak Brewery.

Fields at Locher Hopfen Hop Farm Collective. Photo by Mark Cotterrell of Beak Brewery.

Hop Growing in Tettnang, Germany

Out on the Locher-Hopfen co-operative hop farm, Anton and Florian’s brother Ludwig Locher’s passion for hop growing was clearly evident. The manual labour that goes into producing hops had largely been something that I’d forgotten about. When a pallet of hop pellets arrives at the brewery it’s easy to forget that hops are a seasonal product and require a year of hard work to produce.

“The family aspect of the businesses was very nice. I was struck by how passionate the people behind the ingredients were, both from BESTMALZ and BayWa. Baywa was in a beautiful setting and the brothers were hugely enthusiastic.”

Ludwig Locher at the Locher Hopfen Hop Farm. Photo by Mark Cotterrell of Beak Brewery.

Ludwig Locher at the Locher Hopfen Hop Farm. Photo by Mark Cotterrell of Beak Brewery.

For hop growers, we learned the importance of contracting not only to help the growers plan which varietals to grow, but even in terms of planning their labour requirements for the next year. I was fascinated that some of the old, naturally selected varietals are much harder to process with modern machinery compared to the newer varietals which have been developed with modern growing and picking methods in mind.

For example the fact that Tettnang can grow so quickly in the summer months that each bine needs to be manually retrained as it loses the wire following the sun over the course of the day was fascinating. In the styles that most new breweries like Bullhouse produce, German hops are a rarity, however I’ve definitely taken away the possibility that some German aroma varieties may be useful to achieve a base level of citrus/grapefruit aroma prior to a Mosaic® or Citra® dry hop.

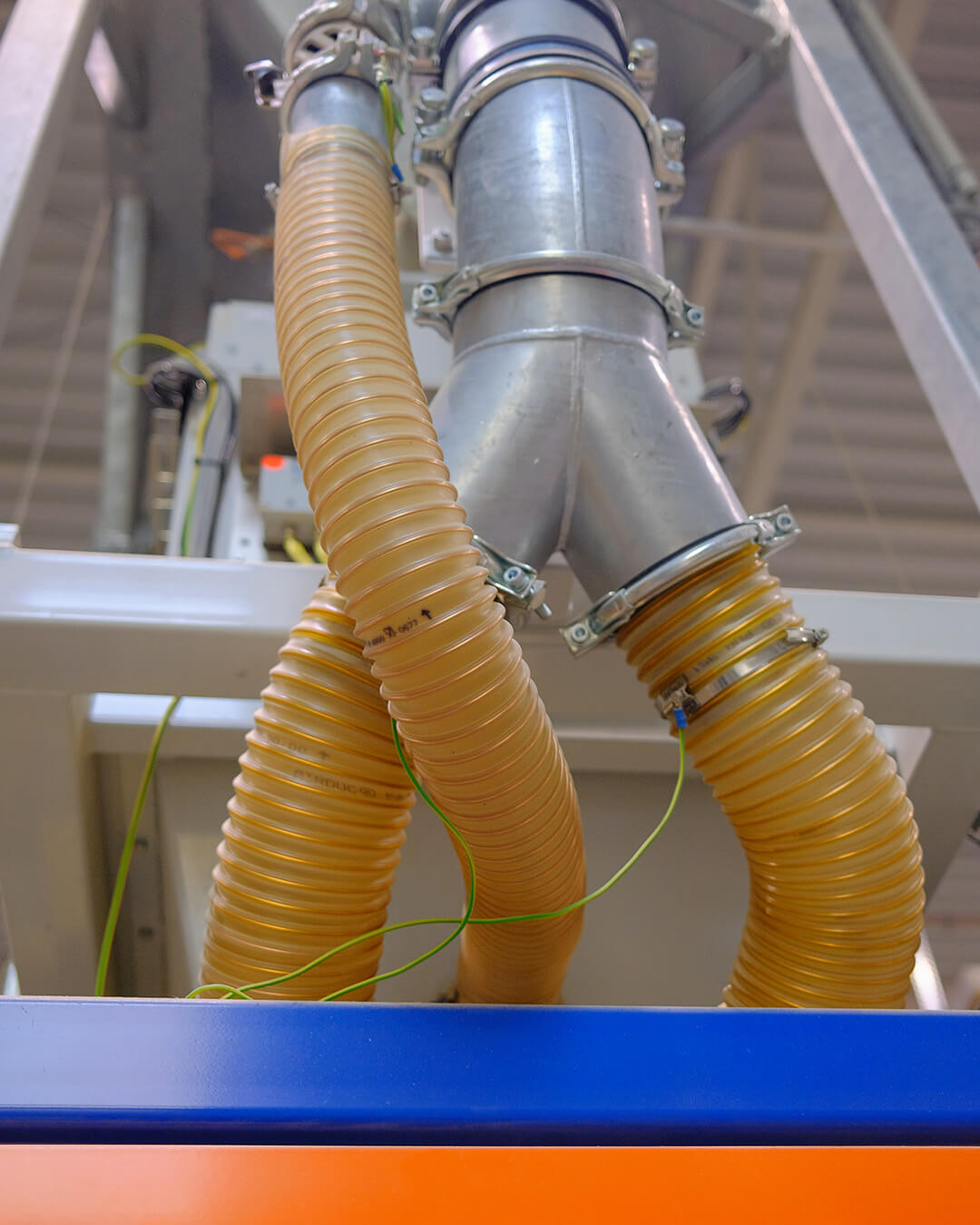

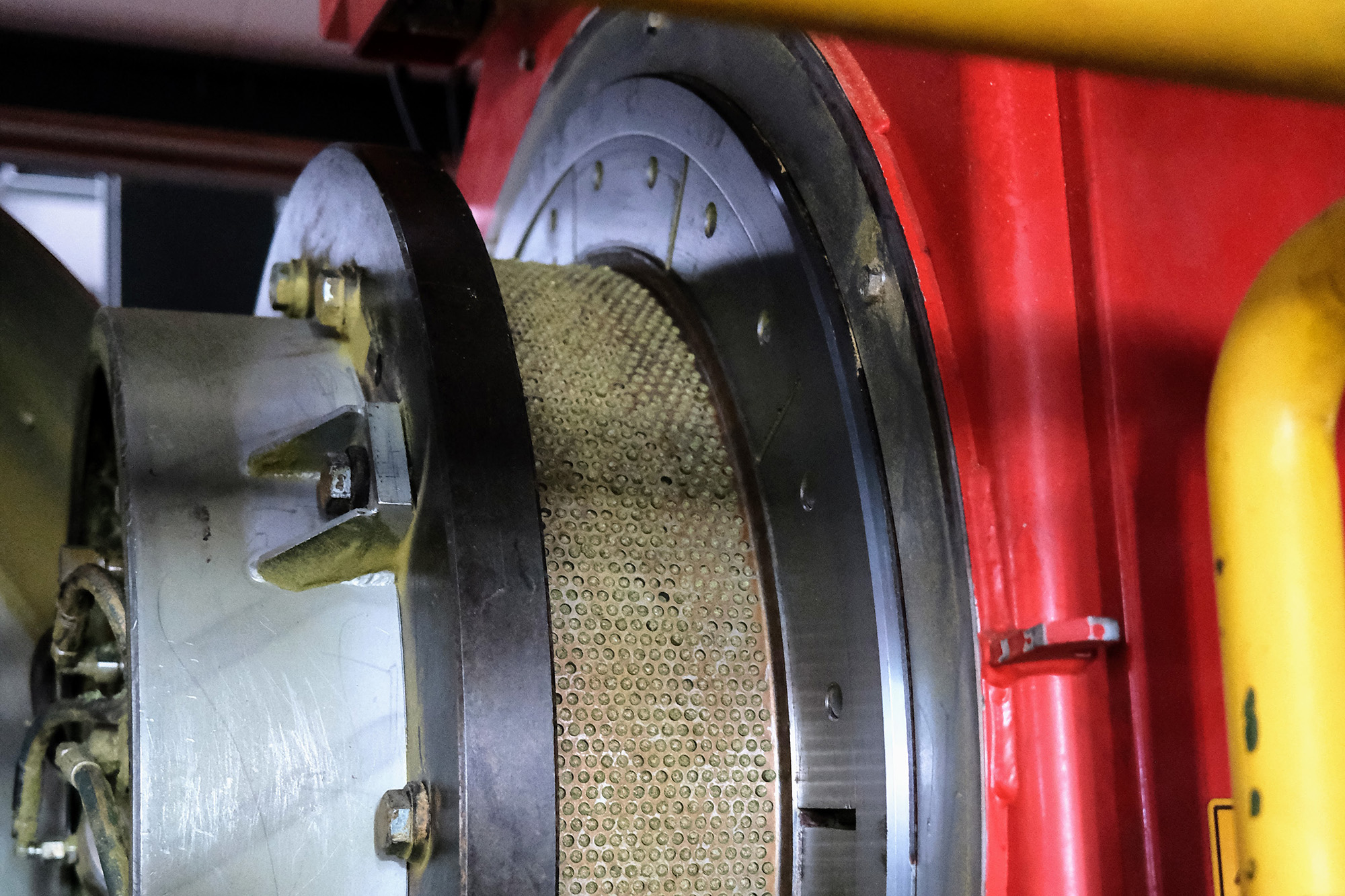

Pelletiser at BayWa Hop Production Facility in Tettnang. Photo by Mark Cotterrell Beak Brewery.

Pelletiser at BayWa Hop Production Facility in Tettnang. Photo by Mark Cotterrell Beak Brewery.

“[For some US craft breweries, it can be] that some US hops might get substituted [for German hops]... using Callista for tropical fruit flavours, not as a single hop because you need more punch, but to reduce [the levels of] like the Mosaic®, the El Dorado® a little bit by adding this [Callista] so this reduces the cost.”

The smell in the kiln will live long in the memory, and the smell of smoke from the pubs will live on my clothes until they go through the washing machine! Smoking inside pubs in Baden-Württemberg was definitely a surprise.

Locher Hopfen Hop Farm in Tettnang. Photo by Mark Cotterrell of Beak Brewery.

Locher Hopfen Hop Farm in Tettnang. Photo by Mark Cotterrell of Beak Brewery.

Inspiration from German Lager Beers

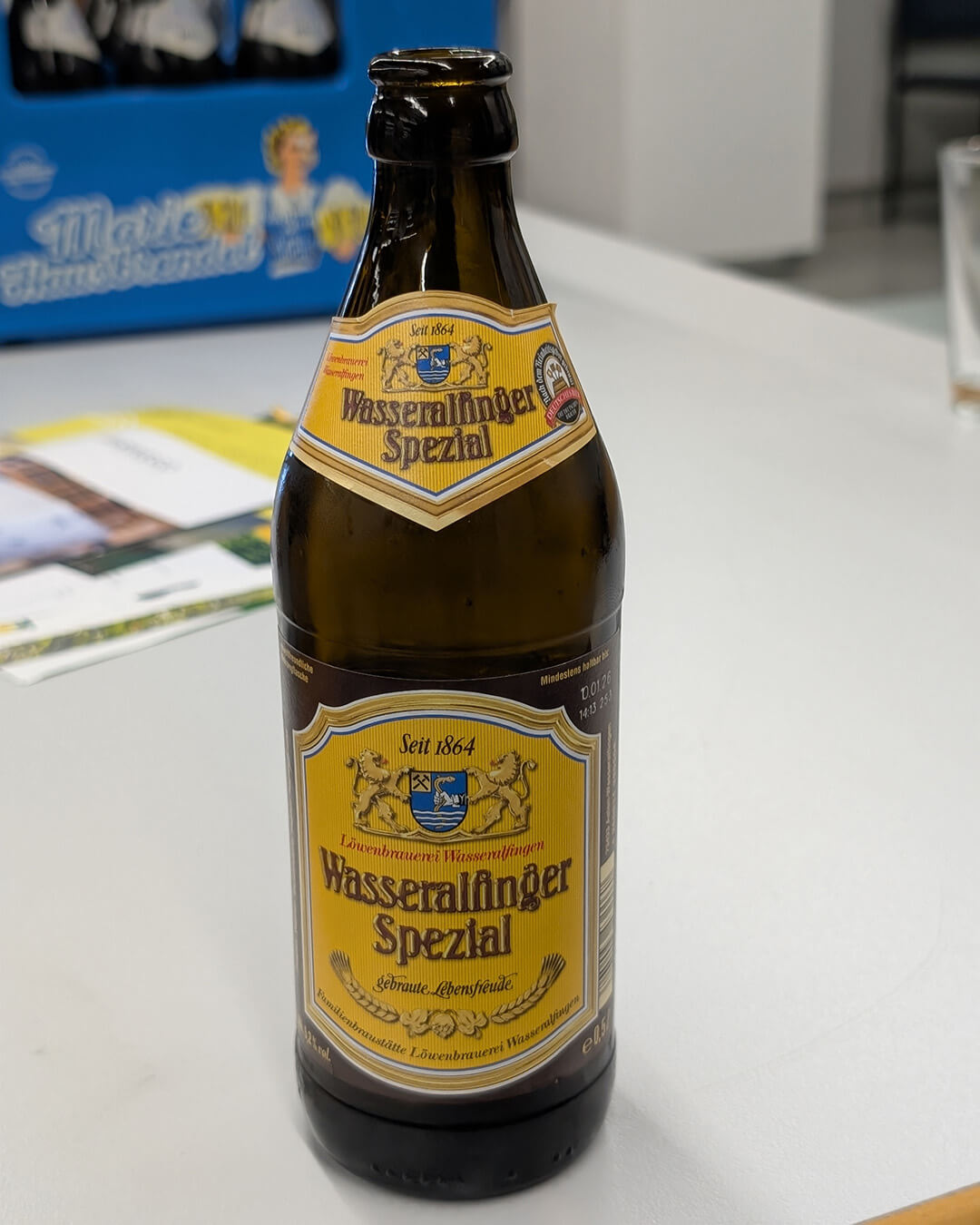

We’ve tended to shy away from brewing too many lager products at Bullhouse, not only because they take longer to produce, and therefore reduce our capacity in the brewery, but also because the quality of imported German beers, and the price they achieve is very hard to beat, however after drinking plenty of lager on this trip I’m excited to see if we decide to expand our repertoire next year.

A beer highlight for me – apart from the standard novelty of being able to purchase world class lager in every shop – was a 5.2% Export Lager from Löwenbrauerei Wasseralfinger called ‘Wasseralfinger Spezial’ given to us by the BayWa team.

Photo by Mark Cotterrell of Beak Brewery.

Photo by Mark Cotterrell of Beak Brewery.

“I think prior to this trip I already held these ingredients in high esteem, but being able to see the process and people behind them only strengthens that conviction.”

Jordan Donnelly (Pearse Lyons Brewery), Harry Szapira (Wicklow Wolf), Ian Anthony (Loughran Brewers Select), Sarah Brennan (Loughran Brewers Select), Natasha Lawlor (Loughran Brewers Select), James Loughran (Loughran Brewers Select), Mark Cotterrell (Beak Brewery), Caitlin McErlean (Track), Doug Rowe (Tempest Brewing Co.) & William Mayne (Bullhouse Brew Co.)

Jordan Donnelly (Pearse Lyons Brewery), Harry Szapira (Wicklow Wolf), Ian Anthony (Loughran Brewers Select), Sarah Brennan (Loughran Brewers Select), Natasha Lawlor (Loughran Brewers Select), James Loughran (Loughran Brewers Select), Mark Cotterrell (Beak Brewery), Caitlin McErlean (Track), Doug Rowe (Tempest Brewing Co.) & William Mayne (Bullhouse Brew Co.)

“It was truly inspiring to meet passionate suppliers who care as much about what they are doing as much as we do, and who give us the best possible chance of making world class beers for all our customers.”

Independent Family Owned German Ingredient Producers & Independent Breweries – A Perfect Combo

Huge thanks to the Loughran team for the invite, and to the rest of the brewers for making the trip so enjoyable. The German hospitality was second to none but I’ve definitely consumed my year’s allocation of lager and schnitzel!

Footnote – I had been hoping to repay the wonderful German hospitality by commiserating with some disappointed Germans when Northern Ireland faced Germany in the World Cup Qualifiers in Belfast on Monday night, but sadly it was not to be! [Northern Ireland lost 1-0, but gave a good account of themselves].